OIL BERLIN

What does the brand stand for?

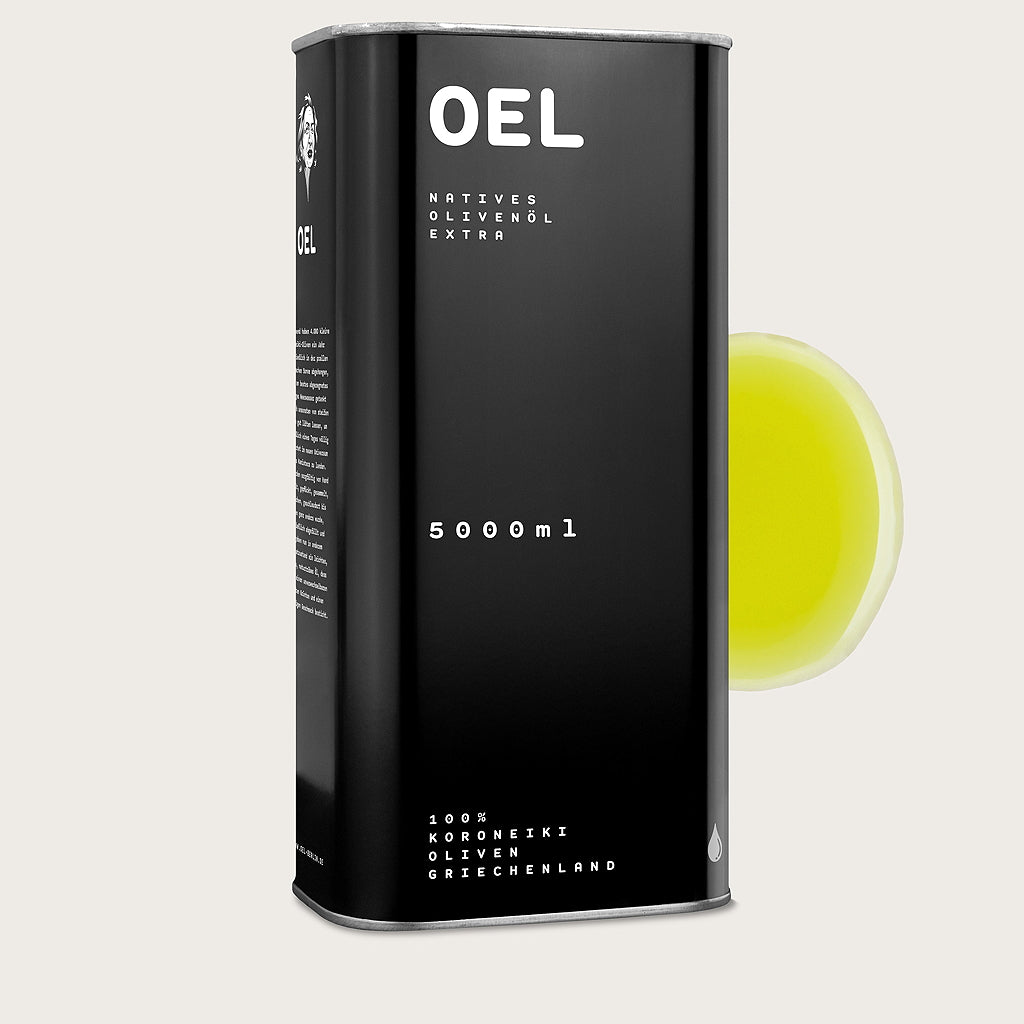

Under the OEL brand, we produce our own organic extra virgin olive oil and sell excellent and innovative organic olive products.

OEL wants to offer special Greek organic olive products of the highest quality at fair prices and sees itself as a direct bridge between producers and consumers, between Kalamata and Berlin.

Organic extra virgin olive oil from Greece

The OEL brand stands for 100% pure Greek organic extra virgin olive oil of the Koroneiki variety. The olives grow on our own trees and those of our local partner in Kalamata/Messenia/Greece. All groves are harvested by hand. We actively participate in harvesting and production every year. You can find out more about harvesting and production below.

With a history stretching back almost 5,000 years, olive oil is considered one of humanity's oldest agricultural products - and the history of Thalassa also begins with OEL olive oil ...

Not just buying Greek olive oil and then selling it, but buying our own land and cultivating our own olives - that was our idea, and we decided to do it in 2015.

We wanted to have the entire production chain in our own hands and therefore be able to control it. Kalamata, the capital of the Messinia region in the Peloponnese, is not only our (second) home, but also that of millions of olive trees. The region is considered the most important olive growing area in Greece, ahead of islands such as Crete and Lesbos. They have been cultivated around Kalamata for thousands of years.

The regionally most important olive variety is the Koroneiki olive.

For good reason: the taste of the small green Koroneiki olive is legendary and its composition is unsurpassed. There is a reason why Koroneiki oil is the most popular olive oil in Greece.

But the geography and climate of the Messinia region also play a decisive role in the taste of OEL olive oil. The mountainous, extremely dry, stony region, which is very hot in summer, demands a lot of robustness and composure from the trees and the farmers. The result is an olive oil with flavors of citrus fruits and nuts.

Producing OEL means pure manual work.

The harvest of OEL takes place once a year, usually from the beginning of November. Then our olives make their way from the tree into our canisters.

This is how we harvest our olives

The olive harvest, which takes place every November and December in the Messinia region, is a complex, planning-intensive and labor-intensive process. During harvest, the days begin when the sun rises and end when it sets.

But when is the optimal time for the olive harvest?

As the year comes to an end, we closely monitor the ripeness of the olives so as not to miss the right harvest time for the best taste of the olive oil. The degree of ripeness of an olive can be determined by its size, surface tension and color. In our case, the color development turns the young, green fruits into dark purple olives. However, the harvest takes place before the fruits are fully ripe

When harvesting, we work our way through the entire grove from tree to tree. First we spread large, fine-mesh nets under the tree. These nets catch the olives that have been fanned out and prevent them from simply falling to the ground.

Once the nets are placed correctly, it starts:

A person climbs into the crown of the olive tree and saws particularly strong branches out of the tree. The tree pruning takes place in parallel with the harvest. Since the olives usually bear fruit every two years, large, richly bearing branches can be sawed off without hesitation. They would produce little to no yield at the next olive harvest. The cut also gives the olive tree the right growth signals, ventilates it and allows maximum light.

The sawn-off branches are freed from the olives by hitting them or holding them in a kind of “combing machine”. In this, rollers with rubber studs rotate at several thousand revolutions per minute. These strip the olives from the branches. The remaining harvest helpers *Insiders work with the shaking rakes, which are up to four meters long. This is the most strenuous part of the olive harvest. With these shaking rakes, we shake the olives out of the branches, branch by branch.

The very small Koroneiki olives are not picked individually, but rather “raked” from the branches.

Once an olive tree has been completely harvested, we roughly remove branches and leaves from the olives and pour them into bags.

And off we go to the next tree! We harvest the olives from the first to the last rays of sunshine.

Handcrafting is the key point for us. For OEL we go beyond the requirements of the European organic label. We carry out all land care and harvesting tasks by hand. Fighting weeds and weeds, cutting the trees, fertilizing the soil, painting the tree trunks with lime paint and harvesting the olives is all done by hand at OEL.

Due to competition, time and price pressure, industrial agriculture often carries out super-intensive cultivation and subsequent fully mechanical harvesting. Super-intensive cultivation means that the olive trees are densely arranged in rows for optimal use of the space and are reduced to bush size through targeted regular trimming for fully automated harvesting. To harvest, so-called stilt tractors drive over the small trees. These tractors are taller than the “trees”. They grab the trunk with gripping arms and shake the olives out of the tree. At the same time, huge brush arms drive through the shaken tree and wave the remaining olives out of the branches. Such harvesting causes lasting damage to the olive tree and causes other, ever-increasing problems such as bird deaths.

The splendor, power, strength and individual growth habit of the mythical olive tree can no longer be seen in these plantations.

We don't want that.

Nothing works without Ilias, our partner in Greece. He is the master of the ultra-modern oil mill. Usually until late at night.

This is how we produce OEL organic extra virgin olive oil

At the end of each day, during the olive harvest, which often lasts for weeks, the harvest sacks are picked up by community-organized tractors and taken to the oil mill.

After the harvest, time is the decisive factor: in order to preserve the rich ingredients of the olive, it is important that oil is produced from the harvested olives within a few hours. Otherwise the olives risk oxidizing or breaking in the heavy harvest sacks. That's why our daily work is processed on the same evening.

In the oil mill, the olives are sieved, separated from branches and leaves and then washed - while the exhausted, unwashed harvest workers look proudly at their harvest after a hard day of olive harvesting.

After the washing line, the olives go into the mash tanks. A rotating cutting blade turns the olives into the so-called mash pulp in these containers. When the olive mash is ready, it either goes into the press or, as in our case, into the centrifuge. This is where it is decided whether an olive oil is cold-pressed or cold-extracted during production. The press presses and the centrifuge extracts. Our olive oil is extracted in a centrifuge at several thousand revolutions per minute and then immediately bottled with UV and temperature insulation. The centrifuge is proven to be the gentlest method for processing olives after harvest.

Important: The entire processing facility must be cooled with additional water during production. The temperature of an extra virgin olive oil must not exceed 27 degrees during its production. This is important to protect the ingredients. Only under this condition can olive oil be called “cold-pressed” or “cold-extracted” and therefore “extra virgin”.

Another factor that is crucial both in the olive harvest and in the production of olive oil is the avoidance of contamination. Impurities can negate all the efforts described above and can be detected in both chemical and sensory analyses. Contamination can arise from:

Incorrect harvesting materials - nylon bags instead of linen bags when using machines, especially old machines due to incorrect fertilizers or weedkillers, lack of or incorrect cleaning of processing equipment before and during production

Out of caution against contamination that can quickly creep in, we only use sustainable materials for harvesting and processing, harvesting by hand and relying on our production partner and their state-of-the-art processing facility.

Discover OEL Berlin now